ABOUT US

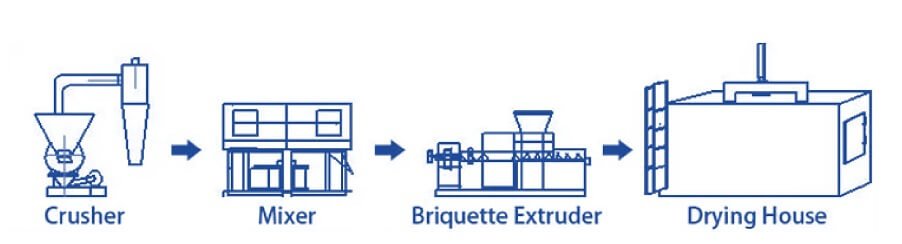

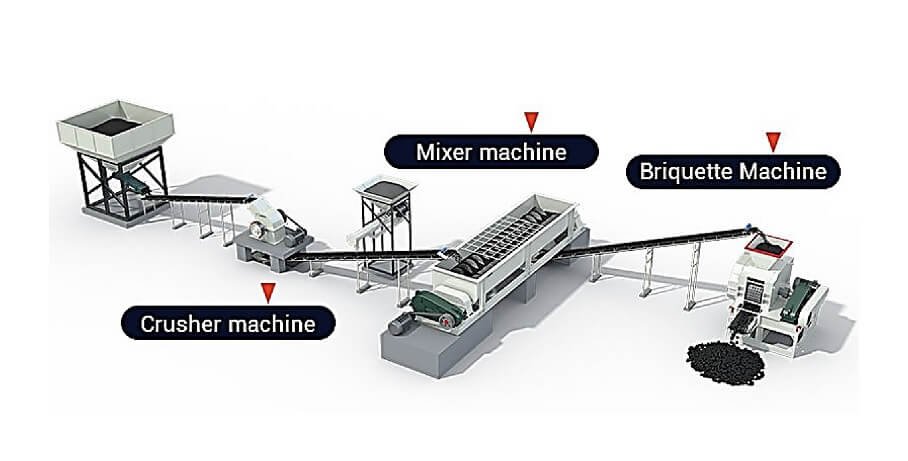

Coconut charcoal briquette Plant. The coconut shell briquette machine is the forming equipment in the production line. It can press all kinds of powdery materials into blocks. The most common ones are, for example, coal powder molding, ore powder molding, desulfurization gypsum molding, coke powder molding, iron filings, various metal slag molding, etc.

The coconut charcoal briquette manufacturing line has the features of easy operation, low cost, and high return. So, our project will offer many job orders for local labore.

The coconut shell charcoal briquette production line includes a hammer mill, storage bin, carbon powder wheel mill, distribution bin, carbon powder briquette machine, continuous mesh belt dryer, packaging machine. In addition, the intermediate conveying device is also essential. Below I will focus on the toner wheel mill, carbon powder briquetting machine, and dryer. Because they are an important factor affecting the quality of the ball.

OUR SERVICES

Coconut Charcoal Powder Mixer

Generally, charcoal can get about 3mm of carbon powder after passing through the hammer mill. However, the higher the fineness of the carbon powder, the better the forming effect of the coconut charcoal briquette. Therefore, on the one hand, the use of a charcoal dust wheel mill can make the material more delicate and help to shape it. On the other hand, after the carbon powder, binder and water are stirred by rolling, the material can fully lock the water and improve the internal viscosity of the molecule

Coconut Shell Crusher Machine

Coconut Shell Shredder is also called coconut shell shredder, hammer crusher. It is suitable for the crushing of mid-hard and light erosive materials, whose pressure resistance strength is no more than 100Mpa and humidity lower than 15%, such as coal, salt, chalk, gypsum, blocks, limestone, etc. Shredder machine can be also used for crushing wood branches, chips, rice, straw, wheat straw, corn straw, grass, river reeds, palm husk, soybeans husk, coffee husk, paddy straw, sunflowers stalk, bamboo and other agro- waste etc.

Working:

Hongrun Coconut Shell Shredder is a kind of crusher shreding the material into fine particles. A hammer crusher is essentially a steel drum containing a vertical or horizontal cross-shaped rotor on which pivoting hammers are mounted. The hammers are free to swing on the ends of the cross. The rotor spins at a high speed inside the drum crashing the material fed into the feed hopper. The material is impacted by the hammers on the ends of the rotating cross and thereby shredded and expelled through screens in the drum.

Coconut Charcoal Briquetting machine

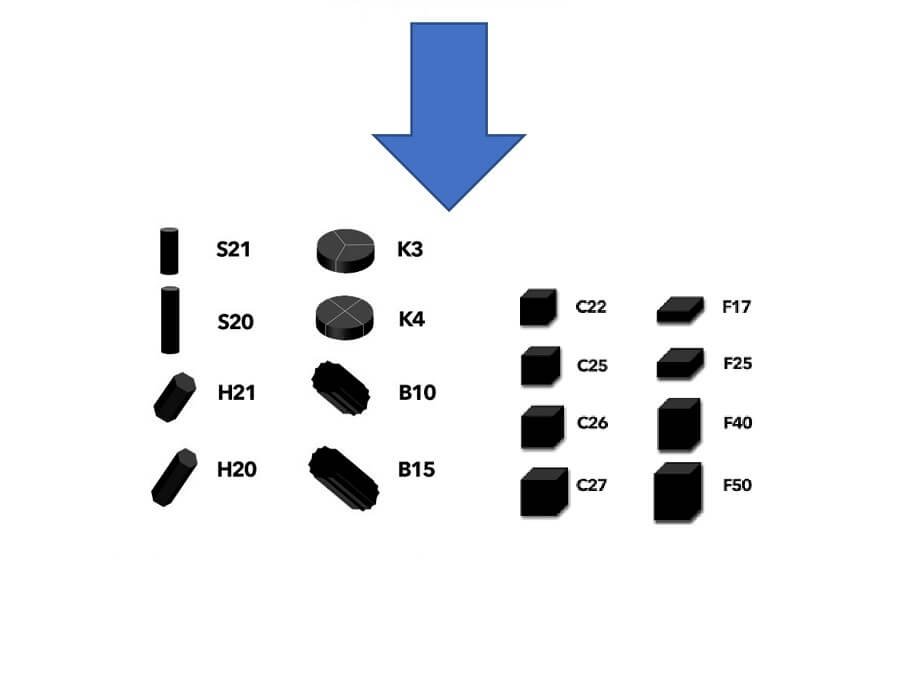

1. This sawdust briquette jute sticks wood charcoal making machine can press coal/charcoal powder into stick shapes, with hole or without hole.

2. It can press the powders into different shapes by changing differ ent molds.

3. Sawdust briquette jute sticks wood charcoal making machinecan produce solid or hollow shaped briquette for barbecue.

4. The final briquette can be used as fuel, BBQ, boiler and so on.

WHAT MAKES US SPECIAL

The heat pump dryer uses the air around the environment to transfer heat to the surface of the material to wet the surface. With the latest cold, warm air drying system, drying temperature of heat pump dryer ranges from 10°C to 85 °C. It is more more effectively than any traditional drying equipment in protecting the drying material color, smell, taste, individual form and nutrition.

The multifunctional drying unit has its own control system and drying software system, which can reasonably control the drying temperature, humidity and time, and can set different drying temperatures and humidity in multiple time periods. The adjustable program can ensure that different parameters are entered when drying a variety of different products. It can be widely used in fruits, vegetables, other agricultural products, fish, shrimp and other seafood, cocoa beans, coffee beans, tea, spices and other economic crops. One year can guarantee continuous work for 12 months